Above 85 dB, a person’s health may be at risk. It’s bad for your whole body, not just your hearing. Excessive noise in the home or workplace has been linked to health problems such as hypertension, insomnia, and a lack of concentration. More than 80 decibels (dB) of sound pollution may be caused by the sounds of traffic, construction activities, and loud music.

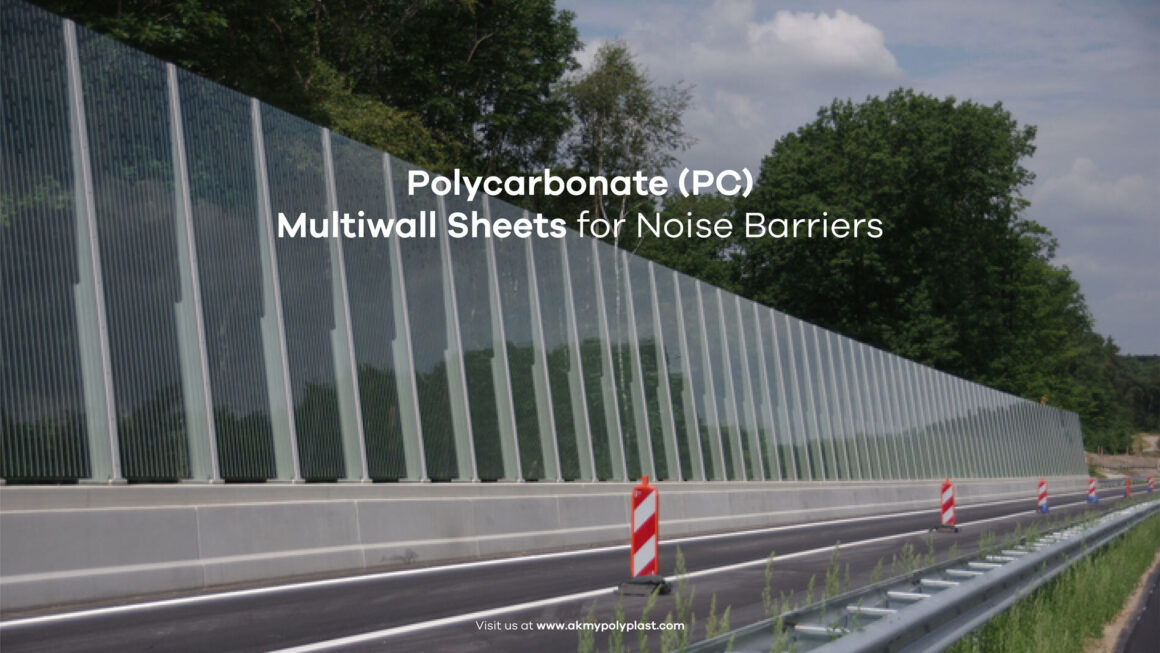

For individuals who live near motorways, noise barriers have become an essential part of city life. Designing a noise barrier is a great way to keep out unwanted sounds, and we’ve covered it in-depth in our article. Noise barriers may be constructed from various materials, including trees, bushes, hills, and more modern materials such as wooden fences, rubber, and plastics. Polycarbonate (PC) sheets and PMMA are just a few examples of these cutting-edge materials.

So, what are the unique characteristics of polycarbonate (PC) noise barriers? What is the purpose of using this material in designing a noise barrier? In addition, what are the advantages of PC noise walls? PC noise barriers and PC sheets will be discussed today at AKMY Polyplast.

Do you know where sound pollution has a greater impact on people?

Because of the high volume of vehicles on city streets, residents in large metropolitan areas may be at risk of developing ailments related to noise pollution. Constructive activity in the neighborhood may also lead to health issues and psychological or sleep disturbances. Noise pollution affects not just humans but also animals. Communication between animals is hampered by the lack of telephones and mobile phones. To communicate with one another, they utilize their voices. They cannot converse effectively within their community due to the excessive noise in the surrounding area.

Have questions about our plastic?

If you’re a distributor, fabricator, designer, we’d love to hear from you. You can WhatsApp us at +91 9643322315 for immediate assistance.

Looking for a specific sheet or polymer? View Our Catalog

Polycarbonate (PC) is a kind of plastic. Thermoplastic polycarbonate, derived from petroleum, is a translucent, formless substance. Because it is transparent, polycarbonate is commonly substituted for clear or semi-clear glasses. Polycarbonate is used in the following applications or products:

- Bulletproof glasses

- Glasses,

- Industry automobiles

- Health care equipment

- Compact discs (CD)

- Greenhouses

- Luminaire for the Outside

There are several other uses for this. Polycarbonate is a popular material since it is resistant to impacts and transparent.

The thermoplastic nature of the material is its most essential attribute. Thermoplastic materials become moldable but solidify upon cooling when heated to a certain temperature. Even after cooling, their characteristics remain the same. As a result, they may be re-used when they change the form. Additionally, this characteristic makes it re-usable.

In addition to being amorphous, polycarbonate is also crucial. When heated, amorphous materials do not immediately melt. Amorphous materials are easier to reshape since they change form more slowly. Polycarbonate is an ideal material for noise barriers because of its transparency, durability, and ability to absorb sound.

Noise pollution and Polycarbonate sound barriers.

At frequencies over 500 Hz, glass, acrylic, and polycarbonate panels absorb noise most efficiently. On the other hand, glass and acrylic are more susceptible to breakage and are less translucent than polycarbonate. However, AKMY Polycarbonate is almost indestructible and may transmit 90% of the light it encounters.

In addition to these features, it’s made from sustainable materials, is long-lasting, and comes in several shades. As a result, the most effective way to reduce noise pollution is to use sound barriers manufactured by AKMY Polyplast. Sound barriers may be used to enclose society’s buildings, railway tracks, airport runways, and other places where noise pollution is a problem.

Polycarbonate (PC) Noise Barriers Definition

To construct polycarbonate (PC) noise barriers, we use the polycarbonate material we discussed before in this article. As a result, noise barriers made of polycarbonate sheets are ideal for maximizing sunshine exposure. This form of the noise barrier, on the other hand, is constructed using PC sheets between long poles with the appropriate materials. PC sheets may be made in any length, thickness, color, and transparency degree that the user desires. These impediments were included when the most stringent standardizing requirements were used.

Features of Polycarbonate (PC) Noise Barriers

Noise barriers have several notable characteristics, including:

- The ability to withstand a large number of hits.

- You may make it in whatever thickness you wish.

- The capacity to withstand the elements in any weather.

- The necessary thickness with a distinct edge form.

- Up to 89 percent of the light may get through.

- Excellent capacity to reshape,

- The production process is simple.

PC sheets are well suited for use as noise barriers, as these characteristics demonstrate. However, two of its characteristics stand out above the others.

-

Transparency at the Very High Level

A noise barrier’s primary goal is to reduce roads and trains’ sound levels and protect the neighboring households from the noise.

In addition, employing PC noise barriers may be done;

- Reduce the volume

- Reducing the use of steel in construction,

- Light transmittance is very high.

- The capacity to create a complete and aesthetically pleasing design with the aid of all of these.

Clear PC sheets may help avoid the “tunnel effect,” which has a tired impact on drivers, from occurring. PC sheets may also help avoid blackouts on the road, making it easier to see and drive. Using a PC sheet to form shades away from the roadway will also be more effective.

-

Durability

PC sheets provide the durability and strength needed for roads and lower noise levels.

Why Choose Us?

Polycarbonate Noise barriers are what we provide here at the AKMY Polyplast. However, we also pay close attention to methods and technologies for reducing noise pollution. Also, make an effort to procure cutting-edge manufacturing technologies.